Louis Lambruschi, Parker Energy Grid Tie Division

Power grids are suffering from high peak demands, instability and unpredictable renewables, so utilities are turning to energy storage systems (ESS).

Energy Storage Systems

Many ESS have significant drawbacks: cost, size, efficiency, capacity and scalability. Some are useful for short-term discharge (a minute or so) to maintain grid stability and power quality. Others can supply a rapid response discharge for an hour or more to help regulate frequency during random and rapid demand variations.

Battery ESS

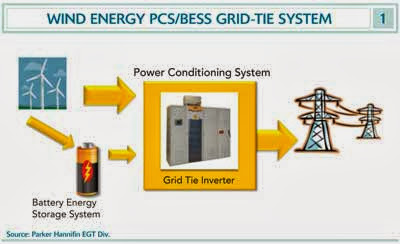

These systems consist of advanced battery chemistries, along with high-power solid-state inverter technology in a power conditioning system (PCS). This combination allows a BESS to supply multimegawatt capacity in a small space. Lithium-ion (Li-ion) batteries have a favorable energy density, size, weight and fast response time, so demand for these systems continues to grow. Benefits of using PCS/BESS in wind farms include:

Frequency regulation during high demand. Because utilities must maintain their output within a narrow frequency range, this is a common application for PCS/BESS. High demand can cause a slight droop in frequency, especially on systems of lower capacity. A BESS can compensate for peak loading with a high-energy discharge through the PCS if it has subcycle response time.

Ramp rate control/capacity firming. This is especially important with wind turbines. In these wind farm apps, the storage element can fill the gaps that occur when output dips because of a major reduction in wind energy.

VAR support. Reactive loading reduces the efficiency of T&D lines, but an appropriately designed PCS/BESS system can compensate by supplying an adjustable range of real or reactive power. This allows more efficient use of power lines and distribution equipment.

Minimizing spinning reserve. Reserve capacity helps maintain output during generator failure or unexpected transmission loss, which could require power reductions to customers. Keeping generator capacity online but unloaded wastes fuel and causes unwanted air emissions. A PCS/BESS can take the place of conventional spinning reserve generation and improve efficiency.

Black start. This capability allows a power plant to bootstrap itself after a blackout, grid connection loss and/or loss of generation capacity. A PCS/BESS can provide the balance of plant power needed for a restart.

Arbitrage/time shifting. This is the storage of low-cost power for later sale at higher prices. Generally this occurs during hours of lower demand if the utility has an ESS.

T&D upgrade deferral. Being able to defer additions to T&D infrastructure is attractive to utilities that are experiencing significant, albeit uneven, growth in power usage. Generally, demand is characterized by ever higher peak loads that occur with increasing frequency. Eventually, existing T&D infrastructure becomes the weak link between a power plant and customers. A utility-scale PCS/BESS system can be deployed quickly near the load to level out power flow and delay a costly upgrade.

PCS/BESS Design for Wind Typically, these highly scalable and modular systems consist of portable containers with rack-mounted batteries tied to the grid through the bidirectional PCS (see Figure 2). The PCS can be configured for various system designs. It converts grid power to DC for battery charging and inverts battery power to AC to feed the grid. BESS design includes cooling for the batteries and the PCS, management and control firmware, data communications links and safety features. Such designs minimize maintenance chores, particularly for PCS inverter modules, which can be swapped out in minutes.

The bidirectional PCS inverter in Figure 2 contains high-power insulated gate bipolar transistors (IGBTs) capable of high-speed switching, full-power delivery in either direction within 10 milliseconds. For DC to AC inversion, this pulse-width-modulated (PWM) switching technology includes automatic synchronization with the AC power grid's frequency and zero crossings. The PCS appears to the grid as a stable synchronous generator. Integral harmonic filters deliver pure sine wave power well within IEEE519 guidelines for total harmonic distortion. The system can provide automated sequenced shutdown and disconnection under power loss in compliance with IEEE 1547 guidelines or can be configured to function in island mode, providing backup power for an isolated microgrid. Good thermal management is integral to the design to protect inverters, batteries and ancillary components. Other elements include devices that monitor operating conditions, detect power quality and provide protection in case of thermal or electrical overload conditions.

Cooling system design in grid-tie inverters traditionally has relied on air or liquid water-glycol cooling. Air cooling has low heat exchange efficiency. Chilled water-glycol requires a substantial volume through the system, which consumes significant space and power, and raises concerns about corrosion and other maintenance issues. To address them, the modular PCS system in Figure 3 has a patented low-pressure R134a (dielectric and noncorrosive) refrigerant that cools the IGBTs. This system removes 930 British thermal units per pound of R134a at a pump rate of 0.3 GPM. Benefits of Modular Design

The cooling system is self-contained for all installed modules. Power connectors and no-leak refrigerant connectors are in the rear of the rack. Connections are made when a module is slid into the rack. Modules can be removed or installed through the front cabinet door without manipulating power wiring. One compact rack can handle more than 1 MW of continuous power transfer.

Modular BESS designs (see Figure 3) can be implemented in configurations (see Figure 4) to meet utility needs. Modular designs facilitate scalability, portability and maintenance, which allow turn-key customization. Modularization starts at the component level and extends to containerized system units. Depending on design capacity, battery modules may be in the same container with the PCS or external to it (see Figure 2). Each phase self-contained module (one per phase) is identical to any other phase module in the system. At 40 pounds, they are replaced easily by one person without ramps or rigging. To further assure long-term reliability, the system can withstand harsh operating environments. PCS and battery containers facilitate personnel access for easier maintenance or service and provide shelter. Comprehensive climate control in the containers maintains optimum operating conditions.

For a safe, secure interface with the grid and BESS, the PCS usually includes switchgear and circuit protection that can take the form of AC or DC contactors, circuit breakers, fused disconnects or a combination (see PCS block in Figure 2).

Current Installations

Installations using grid-connected BESS with batteries and bidirectional PCS inverters include:

AES Laurel Mountain Energy Storage, Elkins, W.Va.: wind farm;

Huntington Beach, Calif.: renewable energy system;

AES Johnson City, N.Y.: BESS installation;

Pasadena, Texas: ERCOT-approved;

AES Corp., Atacama, Chile: Los Andes Copiapo Facility.

Lou Lambruschi is the marketing communications and e-business manager for Parker Hannifin's SSD Drives and Energy Grid Tie Division in Charlotte, N.C. He has 33 years of engineering and application experience in electrical power conversion. Reach him at louis.lambruschi@parker.com or 704-583-8101.

More PowerGrid International Issue Articles

PowerGrid International Articles Archives

View Power Generation Articles on PennEnergy.com

Power grids are suffering from high peak demands, instability and unpredictable renewables, so utilities are turning to energy storage systems (ESS).

Energy Storage Systems

Many ESS have significant drawbacks: cost, size, efficiency, capacity and scalability. Some are useful for short-term discharge (a minute or so) to maintain grid stability and power quality. Others can supply a rapid response discharge for an hour or more to help regulate frequency during random and rapid demand variations.

Battery ESS

These systems consist of advanced battery chemistries, along with high-power solid-state inverter technology in a power conditioning system (PCS). This combination allows a BESS to supply multimegawatt capacity in a small space. Lithium-ion (Li-ion) batteries have a favorable energy density, size, weight and fast response time, so demand for these systems continues to grow. Benefits of using PCS/BESS in wind farms include:

Frequency regulation during high demand. Because utilities must maintain their output within a narrow frequency range, this is a common application for PCS/BESS. High demand can cause a slight droop in frequency, especially on systems of lower capacity. A BESS can compensate for peak loading with a high-energy discharge through the PCS if it has subcycle response time.

Ramp rate control/capacity firming. This is especially important with wind turbines. In these wind farm apps, the storage element can fill the gaps that occur when output dips because of a major reduction in wind energy.

VAR support. Reactive loading reduces the efficiency of T&D lines, but an appropriately designed PCS/BESS system can compensate by supplying an adjustable range of real or reactive power. This allows more efficient use of power lines and distribution equipment.

Minimizing spinning reserve. Reserve capacity helps maintain output during generator failure or unexpected transmission loss, which could require power reductions to customers. Keeping generator capacity online but unloaded wastes fuel and causes unwanted air emissions. A PCS/BESS can take the place of conventional spinning reserve generation and improve efficiency.

Black start. This capability allows a power plant to bootstrap itself after a blackout, grid connection loss and/or loss of generation capacity. A PCS/BESS can provide the balance of plant power needed for a restart.

Arbitrage/time shifting. This is the storage of low-cost power for later sale at higher prices. Generally this occurs during hours of lower demand if the utility has an ESS.

T&D upgrade deferral. Being able to defer additions to T&D infrastructure is attractive to utilities that are experiencing significant, albeit uneven, growth in power usage. Generally, demand is characterized by ever higher peak loads that occur with increasing frequency. Eventually, existing T&D infrastructure becomes the weak link between a power plant and customers. A utility-scale PCS/BESS system can be deployed quickly near the load to level out power flow and delay a costly upgrade.

PCS/BESS Design for Wind Typically, these highly scalable and modular systems consist of portable containers with rack-mounted batteries tied to the grid through the bidirectional PCS (see Figure 2). The PCS can be configured for various system designs. It converts grid power to DC for battery charging and inverts battery power to AC to feed the grid. BESS design includes cooling for the batteries and the PCS, management and control firmware, data communications links and safety features. Such designs minimize maintenance chores, particularly for PCS inverter modules, which can be swapped out in minutes.

The bidirectional PCS inverter in Figure 2 contains high-power insulated gate bipolar transistors (IGBTs) capable of high-speed switching, full-power delivery in either direction within 10 milliseconds. For DC to AC inversion, this pulse-width-modulated (PWM) switching technology includes automatic synchronization with the AC power grid's frequency and zero crossings. The PCS appears to the grid as a stable synchronous generator. Integral harmonic filters deliver pure sine wave power well within IEEE519 guidelines for total harmonic distortion. The system can provide automated sequenced shutdown and disconnection under power loss in compliance with IEEE 1547 guidelines or can be configured to function in island mode, providing backup power for an isolated microgrid. Good thermal management is integral to the design to protect inverters, batteries and ancillary components. Other elements include devices that monitor operating conditions, detect power quality and provide protection in case of thermal or electrical overload conditions.

Cooling system design in grid-tie inverters traditionally has relied on air or liquid water-glycol cooling. Air cooling has low heat exchange efficiency. Chilled water-glycol requires a substantial volume through the system, which consumes significant space and power, and raises concerns about corrosion and other maintenance issues. To address them, the modular PCS system in Figure 3 has a patented low-pressure R134a (dielectric and noncorrosive) refrigerant that cools the IGBTs. This system removes 930 British thermal units per pound of R134a at a pump rate of 0.3 GPM. Benefits of Modular Design

The cooling system is self-contained for all installed modules. Power connectors and no-leak refrigerant connectors are in the rear of the rack. Connections are made when a module is slid into the rack. Modules can be removed or installed through the front cabinet door without manipulating power wiring. One compact rack can handle more than 1 MW of continuous power transfer.

Modular BESS designs (see Figure 3) can be implemented in configurations (see Figure 4) to meet utility needs. Modular designs facilitate scalability, portability and maintenance, which allow turn-key customization. Modularization starts at the component level and extends to containerized system units. Depending on design capacity, battery modules may be in the same container with the PCS or external to it (see Figure 2). Each phase self-contained module (one per phase) is identical to any other phase module in the system. At 40 pounds, they are replaced easily by one person without ramps or rigging. To further assure long-term reliability, the system can withstand harsh operating environments. PCS and battery containers facilitate personnel access for easier maintenance or service and provide shelter. Comprehensive climate control in the containers maintains optimum operating conditions.

For a safe, secure interface with the grid and BESS, the PCS usually includes switchgear and circuit protection that can take the form of AC or DC contactors, circuit breakers, fused disconnects or a combination (see PCS block in Figure 2).

Current Installations

Installations using grid-connected BESS with batteries and bidirectional PCS inverters include:

AES Laurel Mountain Energy Storage, Elkins, W.Va.: wind farm;

Huntington Beach, Calif.: renewable energy system;

AES Johnson City, N.Y.: BESS installation;

Pasadena, Texas: ERCOT-approved;

AES Corp., Atacama, Chile: Los Andes Copiapo Facility.

Lou Lambruschi is the marketing communications and e-business manager for Parker Hannifin's SSD Drives and Energy Grid Tie Division in Charlotte, N.C. He has 33 years of engineering and application experience in electrical power conversion. Reach him at louis.lambruschi@parker.com or 704-583-8101.

More PowerGrid International Issue Articles

PowerGrid International Articles Archives

View Power Generation Articles on PennEnergy.com

No comments:

Post a Comment